I guess it is time to update my records here. With work, life, and the pandemic time has escaped my attention from posting here.

The good news is that my legs continue to get better from the previous injuries and I have had several sub 9-minute miles while running, which is a big deal for me as part of this recovery.

Breaking it down by month

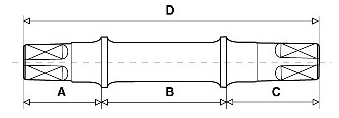

Most of the cycling has been on Kermit as Goose is having bottom bracket issues again. I did have my first on the road flat this summer. I was 12 miles into a ride, about 9 miles from home, and luckily 1.5 miles from a Walmart at 7:00 am on a Saturday morning.

I do keep a tire/tube repair kit on the bike with me although I’ve not had to use it until now. It was the rear tire and it was really worn out so I was hoping Walmart might have a tube and tire I could purchase instead of just trying to patch the old stuff. Of course, the rear tire is more complicated to replace or repair.

I was in luck, they had both tube and tire so outside of the store as the sun was gaining strength, I started the repair. SNAP! The handy little multi-wrench in my repair kit snapped immediately upon first use. Back into Walmart to purchase a small adjustable wrench.

After completing the replacement and pumping as much air as I could with my portable hand pump, I started the 9-mile trek home. I was tired and hungry when I arrived home, but so thankful for how well things worked out.

The weather is starting to cool a bit here in the first week of September and I’m sure before too long I’ll be back to layering clothes to meet the change. Be safe out there folks and keep putting in the work to stay as healthy as you can.